Professional Self-Adjusting Drum Brake Cable Manufacturing

Custom B2B Drum Brake Solutions | No Minimum Orders | Ohio Assembly Since 1956

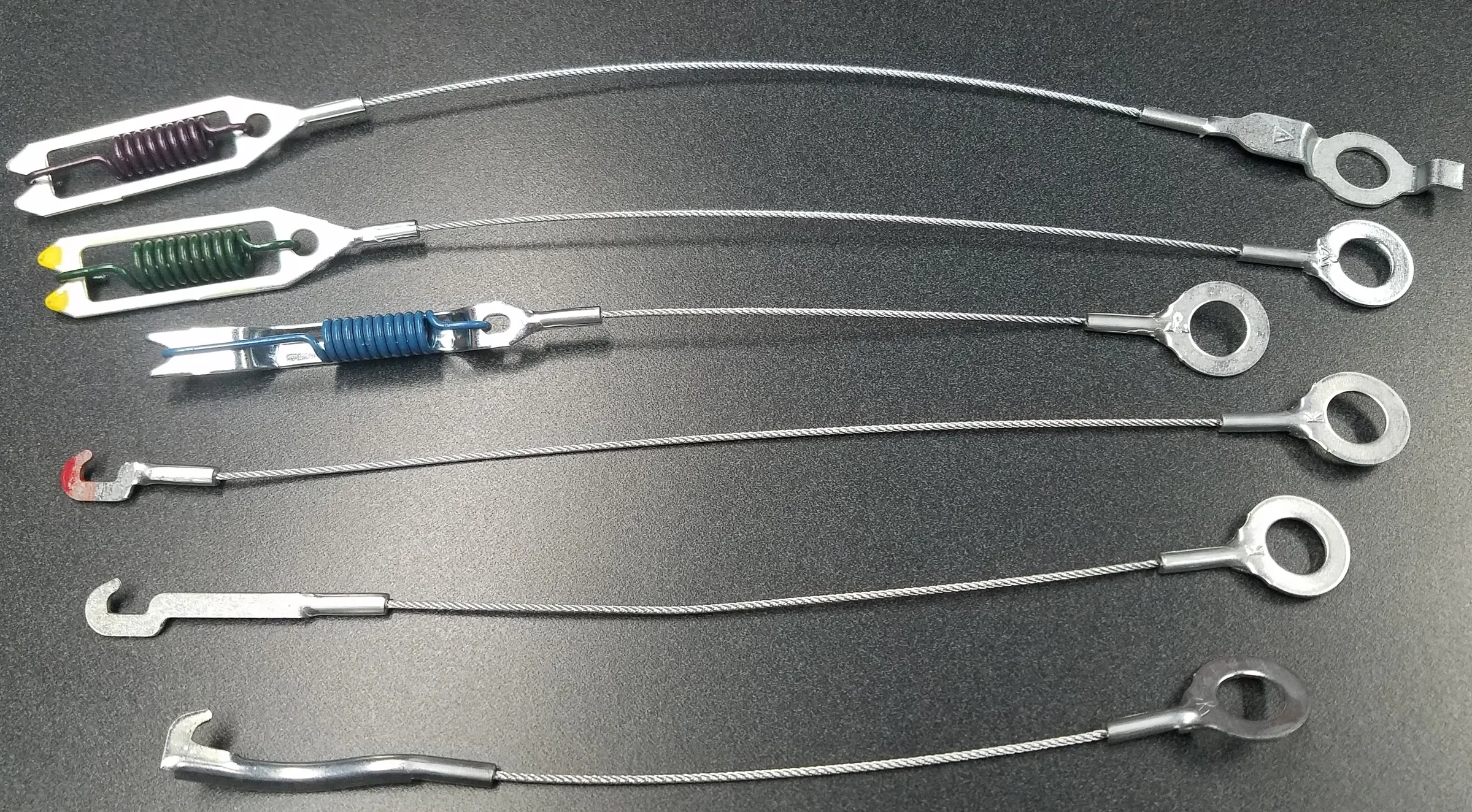

28 brake cable parts for automotive and trailer applications

B2B Manufacturing Excellence

Roy I Kaufman, Inc. manufactures custom self-adjusting drum brake cables for automotive and trailer applications. Our Ohio manufacturing facility combines 65+ years of expertise with in-house automation for competitive production runs. Complete technical documentation and engineering support included.

Request B2B Quote

Production runs from 1-500+ pieces

Specification Verification

Enter your cable measurements for accurate part identification

Verify SpecsEV Co-Development

Engineering partnerships for electric vehicle brake cable systems

Explore EV SolutionsBrowse Our Brake Cable Catalog

Professional brake cables with complete specifications and 3D visualization

B2B Self-Adjusting Drum Brake Cable Manufacturing FAQ

Important Notice

Verify by Dimensions: Always confirm brake cable compatibility by measuring cable length, assembly length, and terminal types before ordering.

Reference Only: Vehicle and trailer fitment information is provided for identification purposes only. Parts are manufactured by Roy I Kaufman, Inc. and are not OEM-branded.