Why Choose Roy I Kaufman for Wire Rope Lanyards?

65+ Years of Expertise

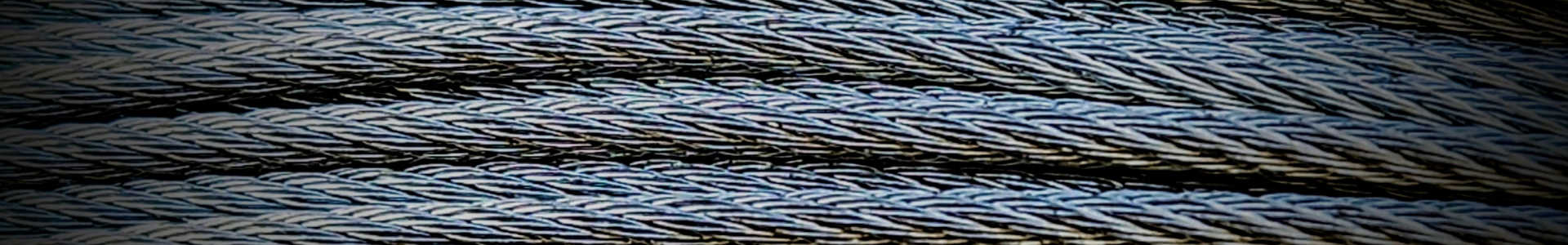

Since 1956, we've specialized in wire rope assemblies, building deep knowledge in small diameter applications and precision manufacturing.

Ohio Manufacturing

Domestic production ensures supply chain resilience, faster delivery, and direct communication with our engineering team.

Automation Precision

Tesla-trained automation engineering brings automotive-grade quality standards to wire rope assembly with consistent precision.

No Minimums, Fast Turnaround

From prototype to production, we manufacture 1 to 10,000+ pieces with quick delivery for urgent projects.

In-House Testing

Pull testing capabilities and quality validation ensure every lanyard meets performance specifications.

Custom Fitting Design & Tooling

We own all our tooling for standard fittings and work with our tooling expert to design and stamp custom end fittings unique to your application.

Product Examples

Standard Utility Lanyards

Small diameter lanyards designed for equipment retention and tethering applications with reliable performance.

Theater Equipment Lanyards

Secondary retention systems for theater lighting, audio equipment, and entertainment rigging applications.

Custom End Fittings

Specialized end fittings and custom attachments designed for specific equipment tethering requirements.

Innovation in Action

Innovative new lanyard solution - see how SwivWasher™ solves equipment retention challenges while preventing cable twist.

Learn MoreWire Rope Lanyard Specifications

Filter and select from our complete range of available configurations.

| Diameter | Construction | Material | Coating | Overall Diameter | Breaking Strength | Working Load | Configure |

|---|

Applications & Industries

Discover how our precision-engineered lanyards serve diverse industries with application-specific solutions.

Shipping & Logistics

- Parts-to-pallet fastening during transit

- Component tethering in packaging

- Hardware retention during shipping

- Assembly line part security

Manufacturing

- Tool tethering in production environments

- Quick-release pin retention

- Control panel component security

- Removable hardware tethering

Entertainment & Theater

- Lighting equipment secondary retention

- Speaker mounting backup systems

- Stage rigging safety cables

- Audio equipment tethering

Marine & Industrial

- Navigation light retention cables

- Marine hardware tethering

- Street lighting bulb safety cables

- CCTV camera backup retention

Material Selection Guide

Galvanized Steel

- Strength: Highest breaking strength ratings

- Cost: Most economical option

- Applications: Indoor, dry environments

- Finish: Hot-dip galvanized coating

Stainless Steel

- Grades: 304 (general) & 316 (marine)

- Applications: Outdoor, marine, chemical

- Temperature: Excellent high-temp performance

- Finish: Bright, maintenance-free

- Corrosion: Superior resistance

Construction Type Guide

7x7 Construction

- Better for static loads

- Higher abrasion resistance

- Permanent installations

- Guy wires and bracing

7x19 Construction

- Higher breaking strength

- Superior flexibility

- Moving equipment

- Theater rigging systems

Coating Selection Guide

PVC Coating

-20°F to 150°F

Key Advantages

- Most economical coating option

- Excellent flexibility

- Wide color selection

- Superior water resistance

Nylon Coating

-40°F to 200°F

Key Advantages

- Superior abrasion resistance

- High-temperature performance

- Outstanding cut resistance

- Chemical resistance

No Coating

Bare wire rope

Key Advantages

- Lowest cost option

- Smallest diameter profile

- Standard industrial choice

- Indoor applications

Technical Specifications & Performance Data

Precision-engineered specifications with automation-validated performance data for technical decision making.

| Construction | Diameter | Breaking Strength | Safe Working Load* | Best Applications |

|---|---|---|---|---|

| 7x7 More rigid |

3/64" (0.047") | 270 lbs | 54 lbs | Ultra-light static loads |

| 7x7 More rigid |

1/16" (0.062") | 480 lbs | 96 lbs | Small equipment, guy wires |

| 7x7 More rigid |

3/32" (0.094") | 920 lbs | 184 lbs | Medium-duty static loads |

| 7x19 More flexible |

1/16" (0.062") | 480 lbs | 96 lbs | Moving equipment, theater |

| 7x19 More flexible |

3/32" (0.094") | 1000 lbs | 200 lbs | Flexible high-load applications |

| 7x19 More flexible |

1/8" (0.125") | 2000 lbs | 400 lbs | Heavy-duty flexible applications |

Material Performance Comparison

Galvanized Steel

- Strength: Highest breaking strength ratings

- Cost: Most economical option

- Applications: Indoor, dry environments

- Finish: Hot-dip galvanized coating

Stainless Steel

- 304 Grade: General corrosion resistance

- 316 Grade: Marine/chemical environments

- Applications: Outdoor, marine, food service

- Finish: Bright, maintenance-free

Protective Coating Options

Enhanced protection and performance through engineered polymer coatings

Why Add Protective Coatings?

Corrosion Shield

Protects base metal from moisture, salt spray, and chemical exposure in harsh environments

Abrasion Resistance

Reduces surface wear from contact with equipment edges, guides, and operating surfaces

Safe Handling

Smooth surface prevents wire rope fraying and reduces risk of finger cuts during installation

Vibration Dampening

Softer coating surface reduces noise and vibration in machinery and structural applications

PVC Coating

-20°F to 150°F (-29°C to 66°C)

0.010" - 0.030"

Key Advantages

- Most economical coating option

- Excellent flexibility for dynamic applications

- Wide color selection for identification

- Superior water and chemical resistance

Considerations

- May stiffen in extreme cold conditions

- Limited long-term UV resistance

- Lower abrasion resistance vs. nylon

Nylon Coating

-40°F to 200°F (-40°C to 93°C)

0.010" - 0.030"

Key Advantages

- Superior abrasion resistance

- Excellent high-temperature performance

- Outstanding cut resistance

- Excellent chemical resistance

Considerations

- Higher material cost than PVC

- Slight moisture absorption (minimal swelling)

- Limited color options (typically clear/natural)

Coating Selection Guide

Marine & Outdoor

Salt spray, UV exposure, weather

PVC RecommendedSuperior water resistance and UV stability for outdoor applications

Heavy Machinery

High wear, frequent movement

Nylon RecommendedMaximum abrasion resistance for demanding industrial applications

High Temperature

Engine bays, heated environments

Nylon RequiredSuperior temperature resistance up to 200°F operating range

Quick Selection Matrix

| Application Type | Temperature Range | Mechanical Stress | Recommended Coating |

|---|---|---|---|

| General Indoor/Light Outdoor | 32°F to 150°F | Low to Moderate | PVC |

| Exercise/Fitness Equipment | 60°F to 200°F | High Repetitive Cycling | Nylon |

| Industrial Machinery | -40°F to 200°F | High Abrasion | Nylon |

| Marine/Offshore | -20°F to 150°F | Chemical + Moisture | PVC |

Coating Termination & Fitting Installation

Standard Installation: Coating is typically stripped from the cable ends (approximately 1-2 inches) to ensure proper mechanical connection of swaged or crimped end fittings. This provides maximum holding strength and reliability for the connection.

Over-Coating Applications: In certain applications where continuous coating protection is critical, end fittings can be applied directly over the coating. This approach may be preferred for marine environments, chemical exposure, or applications where the connection point requires full environmental protection.

Engineering Consultation: Our engineering team will evaluate your specific application requirements, environmental conditions, and performance criteria to recommend the optimal termination method for maximum reliability and service life.

Custom Fitting Capabilities: RIK owns all tooling for standard lanyard fittings and works with our tooling expert to design and stamp custom end fittings tailored to your unique application requirements.

Ready to Order Your Lanyards?

Choose the best option for your precision lanyard project:

Essential Buyer Information

Professional specifications and capabilities for equipment tethering applications.

Lead Times

- Standard lanyards: 1-2 weeks typical production

- Custom tooling: 6-8 weeks initial development

- Subsequent orders: 1-2 weeks after tooling complete

- Rush orders: Available for critical safety needs

Quality Standards

- Cable length tolerance: ±1/16" typical

- Fittings: Manufactured to specification

- Pull testing: Exceeds engineering requirements

- Test capability: Up to 1000 lb capacity

Order Quantities

- No minimum orders - single pieces available

- Typical orders: 500+ pieces for efficiency

- Large scale: Up to 100,000+ pieces

- Safety stock: Available for critical applications

Safety Testing

- Visual inspection: 100% of lanyards

- Dimensional verification: Per safety specifications

- Pull testing: Proof load verification

- Certifications: Test certificates for safety compliance

Need Custom Lanyards for Equipment Tethering?

Our precision manufacturing ensures your equipment stays secure with reliable wire rope lanyards.

Frequently Asked Questions

Common questions about small diameter wire rope lanyards