Custom Wire Rope Cable Assembly Excellence Since 1956

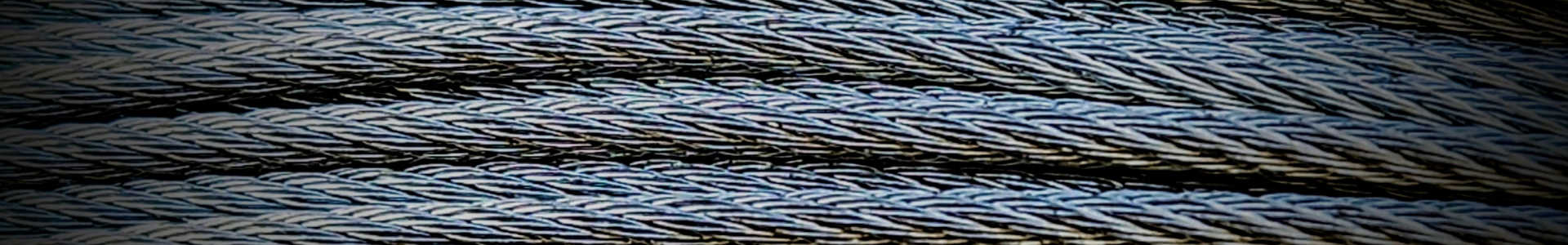

Roy I Kaufman, Inc. has specialized in engineering and manufacturing custom wire rope cable assemblies since 1956, serving diverse industries including automotive, appliance, lighting, fitness equipment, and signage applications. Our custom cable assemblies are precision-built in Ohio, USA using carefully selected domestic and imported components to ensure optimal quality while maintaining competitive pricing.

Our custom wire rope assembly capabilities encompass various constructions optimized for specific applications. Available materials for custom assemblies include 304 and 316 stainless steel for superior corrosion resistance, galvanized carbon steel for standard applications, PVC-coated options for enhanced protection, and nylon-coated cable for specialized applications requiring smooth operation and reduced wear. Our Ohio manufacturing facility maintains rigorous quality standards with comprehensive in-house pull testing capabilities.

What distinguishes our custom wire rope cable assembly service is our commitment to engineering excellence and customer satisfaction. Our in-house automation expertise and advanced manufacturing capabilities enable us to deliver custom solutions with no minimum order requirements and rapid lead times of 1-2 weeks typical. Whether you require prototype custom assemblies for new product development or high-volume production runs, our proven custom manufacturing processes ensure consistent quality and competitive pricing across all project sizes.

Industry-Specific Cable Assembly Solutions

Fitness Equipment Wire Rope Assemblies

Our custom wire rope cable assemblies serve the fitness equipment industry with precision-manufactured cables for weight stack machines, cable crossover systems, and resistance training equipment. We manufacture gym cable assemblies using 7x19 construction for maximum flexibility and durability, with lengths from 2 feet to 20 feet and custom swaged fittings designed for commercial gym applications. Common applications include Nautilus-style weight stack cables, lat pulldown machines, cable crossover stations, and functional training equipment. Our fitness equipment wire rope assemblies meet demanding cycle life requirements with smooth operation and minimal stretch over time, essential for commercial gym environments where equipment must perform reliably under intensive daily use.

Industrial Lighting Suspension Cables

High bay warehouse lighting suspension cables and pendant light wire rope assemblies are manufactured with galvanized or stainless steel construction to support up to 500 lbs per cable. Our lighting suspension wire rope assemblies feature precision swaged fittings, adjustable length options, and corrosion-resistant finishes suitable for industrial warehouse environments, manufacturing facilities, and architectural installations. Popular for LED high bay fixtures, track lighting systems, commercial pendant installations, and architectural lighting displays, these assemblies provide safe, reliable support for overhead lighting with professional appearance and long service life. Available in various diameters with protective coatings including PVC and nylon for specialized lighting applications in corrosive or high-humidity environments.

Appliance and Control Cable Assemblies

Appliance manufacturers rely on our custom cable assemblies for washing machine lid mechanisms, dryer door latches, dishwasher control systems, and oven door counterbalances. We offer PVC coated cable assemblies for washdown applications that resist chemicals and moisture in food processing equipment and pharmaceutical clean room environments. Our appliance control cables use 7x7 construction for flexibility in tight routing paths or 1x19 construction for applications requiring minimal stretch and precise control feedback. These assemblies are engineered to meet UL and CSA requirements for appliance applications with consistent quality manufacturing processes ensuring reliable performance across production runs of thousands of pieces. Available with custom end fittings including ball stops, Z-bends, and stamped terminals to match OEM specifications.

Capabilities

- Constructions: Various wire rope constructions available • Diameters: 3/64"-1/8"

- End fittings: sleeves, studs, thimbles, loops, custom stamped fittings

- Quality assurance: proof-load testing, crimp validation

- Materials: 304/316 stainless steel, galvanized carbon steel, PVC coated, nylon coated

Applications & Industries

Product Examples

Standard Wire Rope Assemblies

High-strength assemblies designed for industrial applications with superior tensile strength and durability.

Wire Rope Light Systems

Suspend lights from the ceiling in industrial, warehouse, stadiums, theatre, or anywhere you can think of.

Custom Eyelet End Fittings

Variety of specialized eyelets designed for specific attachment across various industries and applications.

Related Custom Solutions

Small Diameter Lanyards

Custom small diameter wire rope lanyards for equipment tethering, shipping fastening, and industrial applications.

View LanyardsBrake Cables

Self-adjusting drum brake cables with dimension-first search and cross-reference lookup capabilities.

View Brake CablesInnovation in Action

See our latest engineering solution - the SwivWasher™ addresses fastener retention and prevents cable twist.

Learn MoreCustom Cable Assembly Specifications

Filter and select from our complete range of available configurations for custom cable assemblies.

| Diameter | Construction | Material | Coating | Overall Diameter | Breaking Strength | Working Load | Configure |

|---|

Material Selection Guide

Galvanized Steel

- Strength: Highest breaking strength ratings

- Cost: Most economical option

- Applications: Indoor, dry environments

- Finish: Hot-dip galvanized coating

Stainless Steel

- Grades: 304 (general) & 316 (marine)

- Applications: Outdoor, marine, chemical

- Temperature: Excellent high-temp performance

- Finish: Bright, maintenance-free

- Corrosion: Superior resistance

Construction Type Guide

7x7 Construction

- Better for static loads

- Higher abrasion resistance

- Permanent installations

- Guy wires and bracing

7x19 Construction

- Higher breaking strength

- Superior flexibility

- Moving equipment

- Theater rigging systems

Coating Selection Guide

PVC Coating

-20°F to 150°F

Key Advantages

- Most economical coating option

- Excellent flexibility

- Wide color selection

- Superior water resistance

Nylon Coating

-40°F to 200°F

Key Advantages

- Superior abrasion resistance

- High-temperature performance

- Outstanding cut resistance

- Chemical resistance

No Coating

Bare wire rope

Key Advantages

- Lowest cost option

- Smallest diameter profile

- Standard industrial choice

- Indoor applications

Complete Your Assembly

Custom End Fittings & Tooling Capabilities

Partnering with expert tooling engineers for 30+ years to deliver custom solutions

Proven Tooling Partnership

30+ year relationship with specialized tooling expert for custom dies. We own our stamping dies for consistent quality and faster lead times on repeat orders.

Custom Solutions

Custom tooling development for specialized applications. Usually cost-effective for high-volume production runs. Free consultation to evaluate if custom tooling makes sense for your project.

Standard Wire Rope Fittings

Industry-standard hardware for cost-effective custom assemblies

RIK incorporates industry-standard wire rope fittings into custom cable assemblies. These cost-effective wire rope hardware solutions are available in multiple sizes and materials, compatible with 1/32" to 1/8" wire rope diameters for standard wire rope assembly applications.

RIK Custom Manufactured Fittings

Proprietary stamped fittings designed for specialized applications

Proprietary RIK-manufactured custom wire rope fittings designed for specialized applications. 30+ years of custom stamped fitting expertise with owned dies ensures precision custom tooling for automotive wire rope assemblies, trailer applications, and industrial custom cable solutions.

Assembly Accessories & Options

Value-added options to enhance your custom assemblies

Professional wire rope assembly accessories for complete custom cable solutions. Value-added custom assembly options available on all wire rope assembly orders to enhance functionality, protection, and professional appearance for industrial applications.

Custom Tooling Development Process

When standard fittings don't meet your specific requirements, our proven custom tooling process delivers solutions.

Consultation & Assessment

We evaluate if custom tooling fits your needs and volume requirements. Honest assessment includes recommending standard alternatives when appropriate.

Expert Partnership

Work with our 30-year tooling partner for design and engineering. Leverage decades of experience in stamping die development.

Tooling Development

Custom tooling development depending on complexity. Flexible ownership arrangements available. We manage production and maintain the dies regardless of ownership structure.

Production & Delivery

Once tooling is complete, fast turnaround on orders. Standard lead time: 6-8 weeks for tooling development + 1-2 weeks for production runs.

When Custom Tooling Makes Sense

High Volume

Annual quantities of 10,000+ pieces typically justify custom tooling investment

Unique Specifications

Custom dimensions, materials, or configurations not available in standard options

Industry Requirements

Specific automotive, aerospace, or industrial standards requiring custom solutions

Long-term Products

Stable product lines with multi-year demand to amortize tooling costs

Ready to Get Started?

Choose the best option for your custom wire rope assembly project:

Essential Buyer Information

Professional specifications and capabilities for procurement decision-making.

Lead Times

- Standard assemblies: 1-2 weeks typical production

- Custom tooling: 6-8 weeks initial development

- Subsequent orders: 1-2 weeks after tooling complete

- Rush orders: Available for critical needs

Quality Standards

- ISO 9001:2015: Certification in progress with DNV

- Cable length tolerance: ±1/16" typical

- Fittings: Manufactured to specification

- Pull testing: Exceeds engineering requirements

- Test capability: Up to 1000 lb capacity

Order Quantities

- No minimum orders - single pieces available

- Typical orders: 500+ pieces for efficiency

- Large scale: Up to 100,000+ pieces

- Volume pricing: Available for quantity orders

Test Methods

- Visual inspection: 100% of assemblies

- Dimensional verification: Per specifications

- Pull testing: Proof load verification

- Certifications: Test certificates provided

Ready to Discuss Your Wire Rope Assembly Project?

Our engineering team is standing by to help specify the right solution for your application.

Frequently Asked Questions

Common questions about custom wire rope cable assemblies