EV Drum Brake Cable Manufacturing & Co-Development

Ready when electric vehicles need cable-actuated self-adjusters. We engineer to your specification.

Wire Rope Expertise

Automation Engineers

Prototype Turnaround

Ford & Chrysler Supplier

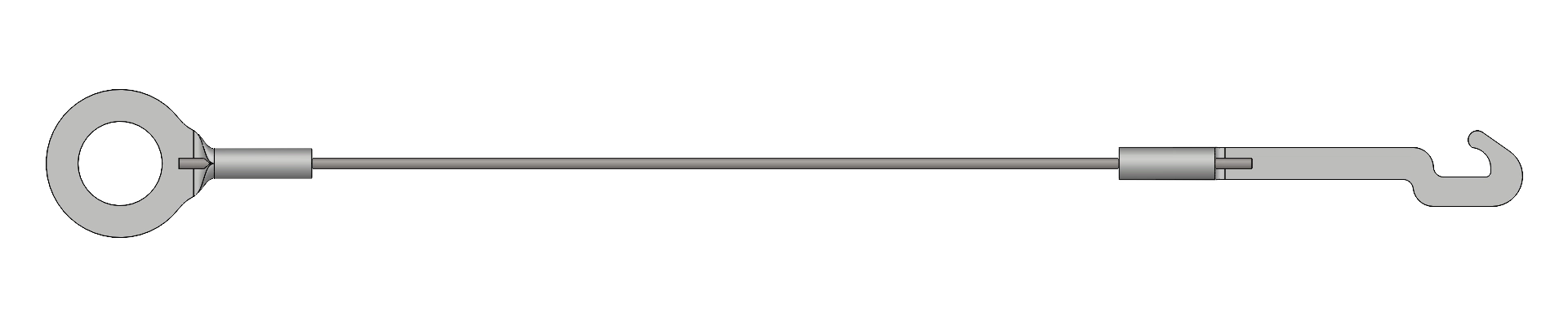

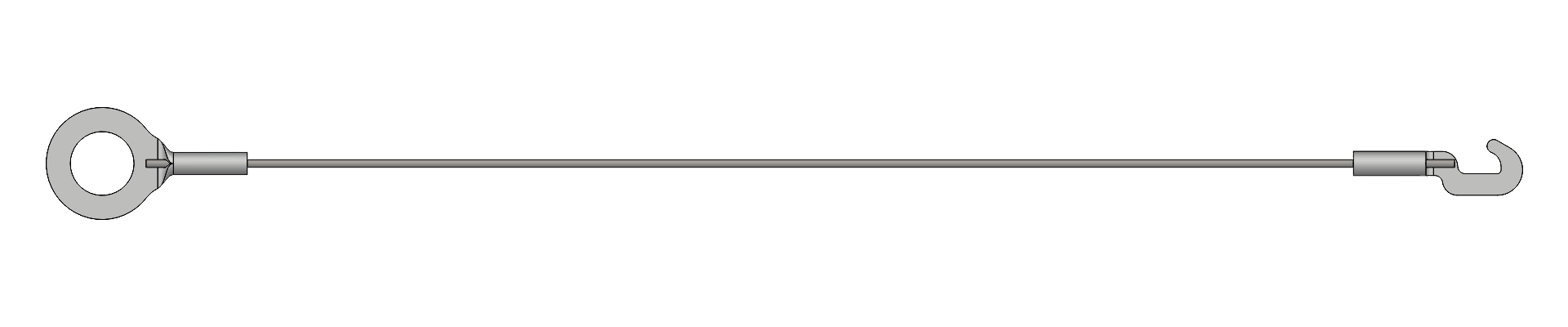

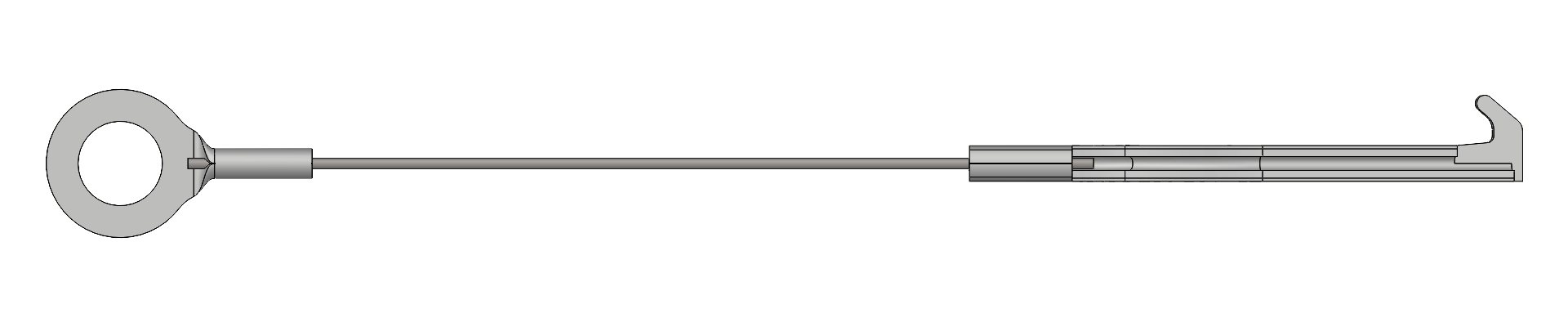

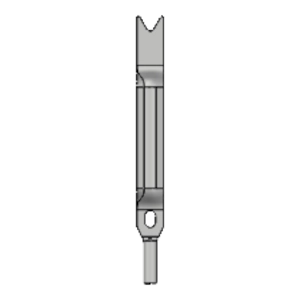

Self-Adjusting Drum Brake Cables (Inside the Drum)

We manufacture the inside-the-drum self-adjuster cable that indexes the star wheel—independent of how the brake is applied (parking cable or in-drum EPB). We build by dimensions and targets: overall length, free cable length, terminal geometry, spring details, environment, and life-cycle.

Why EVs Choose Drum Brakes & Self-Adjusting Cables

Why Drum Brakes on EVs

Perfect for regenerative braking duty cyclesKEY INSIGHT

Regen does the heavy lifting → friction brakes work less

DRUM BRAKE ADVANTAGES

- Enclosed design - Natural corrosion protection

- Low residual drag - Maximizes EV range

- 150,000 km intervals - Continental's VW ID series

REGULATORY DRIVER

Euro 7 brake dust limits:

- 7 mg/km (2025) → 3 mg/km (2035 BEVs)

- Enclosed drums contain particulates

Why Self-Adjusting Cables

Internal star wheel actuator advantagesCORE FUNCTION

Lever + star wheel maintain shoe-to-drum clearance

CABLE ADVANTAGES

- Tunable drag - Every watt matters on EVs

- Packaging flex - Tolerance stackup friendly

- Corrosion proof - 304/316 stainless, coated

- Fast iteration - Length/terminal tweaks vs retooling

OUR APPROACH

Dimension-driven manufacturing:

- OAL + free length + terminal geometry

- Spring details + environment + lifecycle

THE COMBINATION

Regen-friendly drums + precision cable adjusters = Lower maintenance, contained particulates, optimized EV range

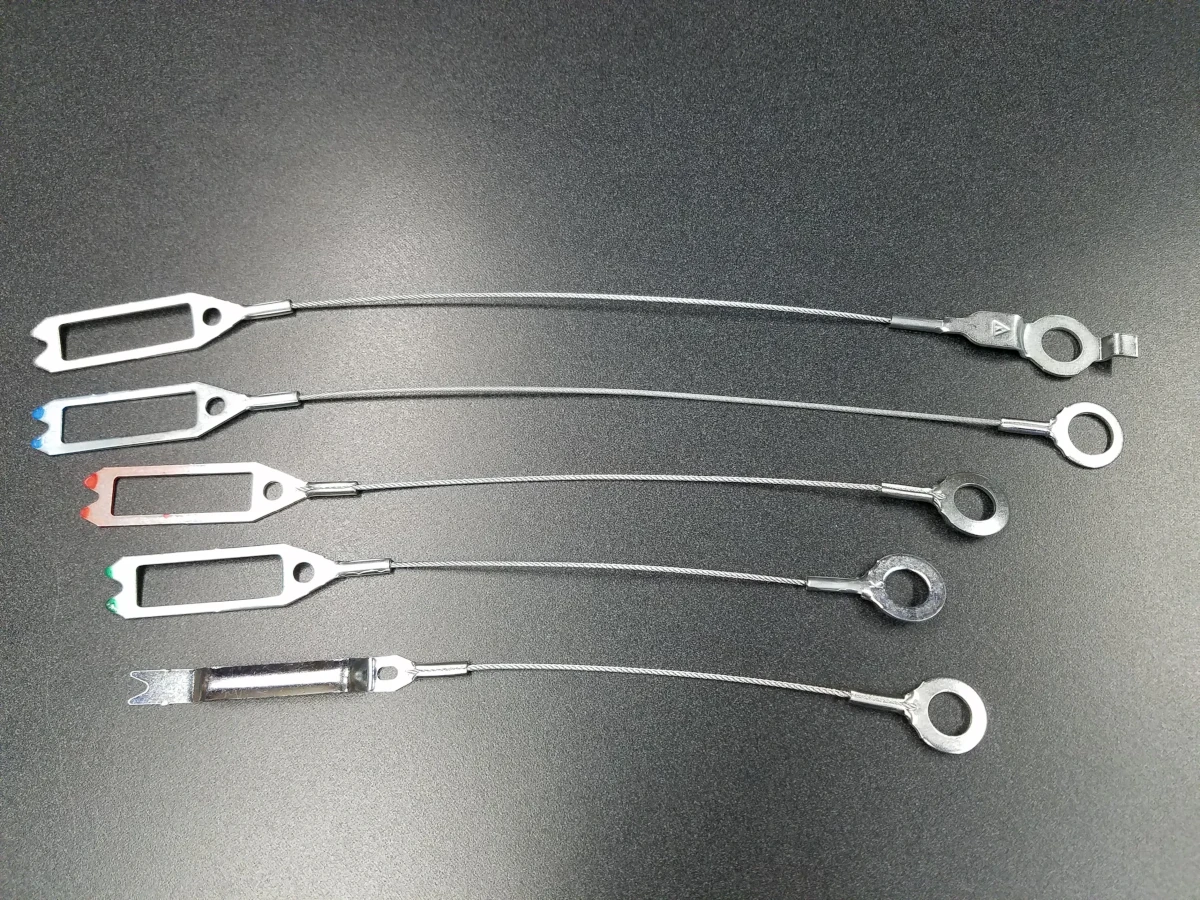

EV-Ready Cable Examples

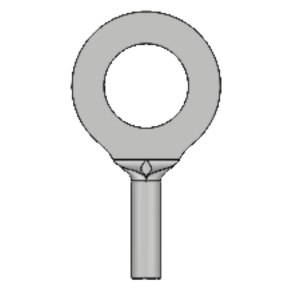

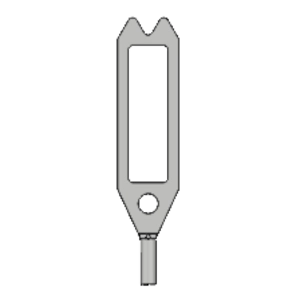

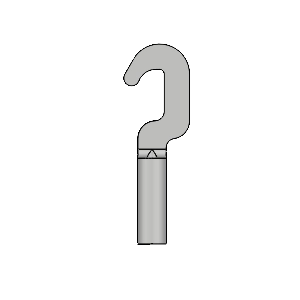

Representative samples showing different terminal and spring configurations

EV-Ready Terminal Options

All terminal types available for custom EV brake cable configurations

What We Offer to EV Programs

Rapid Prototypes

1-2 week turnaround for concept and prototype quantities

Custom Engineering

Terminal configurations, spring options, and dimensional optimization

EV-Specific Materials

Low stick-slip liners and corrosion-resistant coatings

Environmental Testing

Salt-spray, temperature cycling, and durability validation

Design Feedback

DFM guidance from Tesla-trained automation engineers

Volume Scaling

Path from prototypes to high-volume automated production

Request Engineering Consultation & NDA

Share your envelope constraints and let's explore cable solutions for your EV program

Development Partnership Approach

No Current EV Applications: We do not claim existing EV fitments or applications. Our focus is co-development for future programs.

Engineering Partnership: We work directly with your specifications to develop optimal cable solutions for emerging EV brake architectures.